Why Luminy® PLA?

Luminy® PLA has ideal properties for food serviceware: heat resistant up to 100°C, zero flavor transfer, high stiffness, gloss, transparency, good grease and oil resistance, and sustainable end-of-life options. It can be processed on most existing production lines requiring little to no modifications.

The most common Luminy® PLA grades used for food serviceware are:

Whether out of convenience or hygienic necessity, Luminy® PLA aligns with growing consumer demand for sustainable and well-labeled, industrially compostable options while meeting the need for single-use products. Its certifications include:

Brazil is the largest contributor to plastic pollution in Latin America, annually producing about 500 billion single-use plastic items. Casca Brasil, a Brazilian brand owned by Strawplast, has chosen to use PLA Luminy® compounds produced by Earth Renewable Technologies to help change this reality. Casca Brasil is now offering industrially compostable forks, spoons, knives, and straws.

LX175, L105, and L130 are commonly used in food serviceware, but our team will gladly assist you in finding the right grade or blend that is perfect for your specific needs.

Luminy® PLA is food contact approved, making it a great start to the plastics supply chain for companies looking to create packaging for foods. In addition, our product is biobased, compostable, recyclable, and can be transparent. These are all attributes that are attractive to the end consumer and perfect for cutlery and other food serviceware.

Some plastics release unwanted substances that can be dangerous if ingested. That is why it is so important that the plastics used in food packaging be approved for use in food contact applications.

Yes, Luminy® PLA is fully biodegradable. This means that it can be industrially composted, fulfilling the requirements of EN 13432 and ASTM D6400.

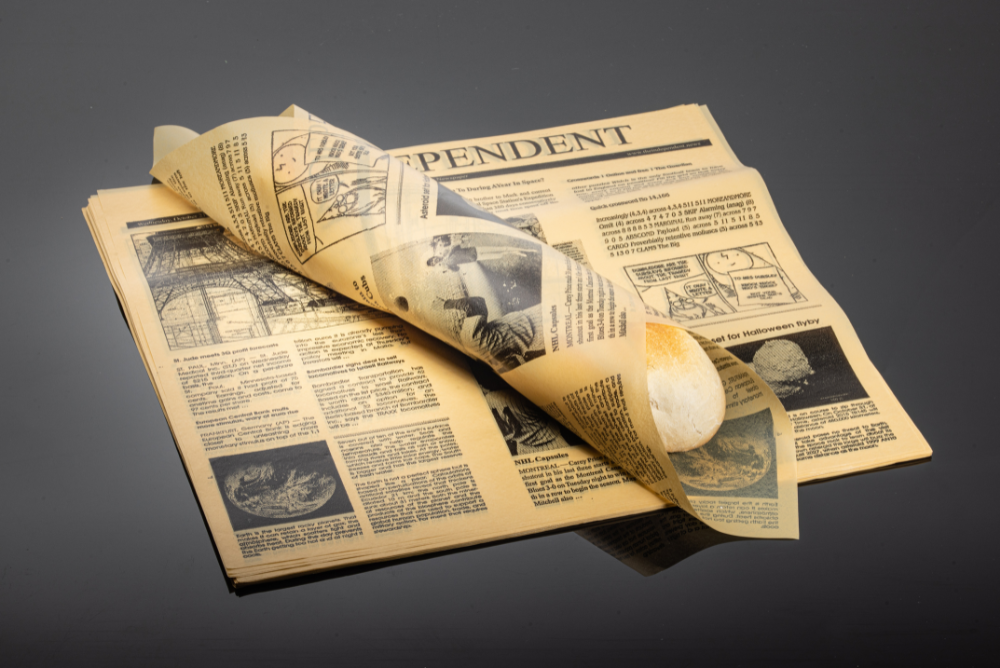

Compostable bioplastics are particularly useful in applications where sorting organic waste from plastic waste is difficult, like with disposable cutlery. Using Luminy® PLA enables these items to go to composting facilities rather than the landfill.

Our Luminy® PLA has an 85% lower carbon footprint compared to conventional plastics. It’s recyclable, compostable, and made from responsibly sourced sugarcane.

Our scientists and experts are always on call. We work alongside your team to help build new applications and ensure a smooth transition to sustainable solutions.

We are driven by our vision of a better world for generations to come.