Why Luminy® PLA?

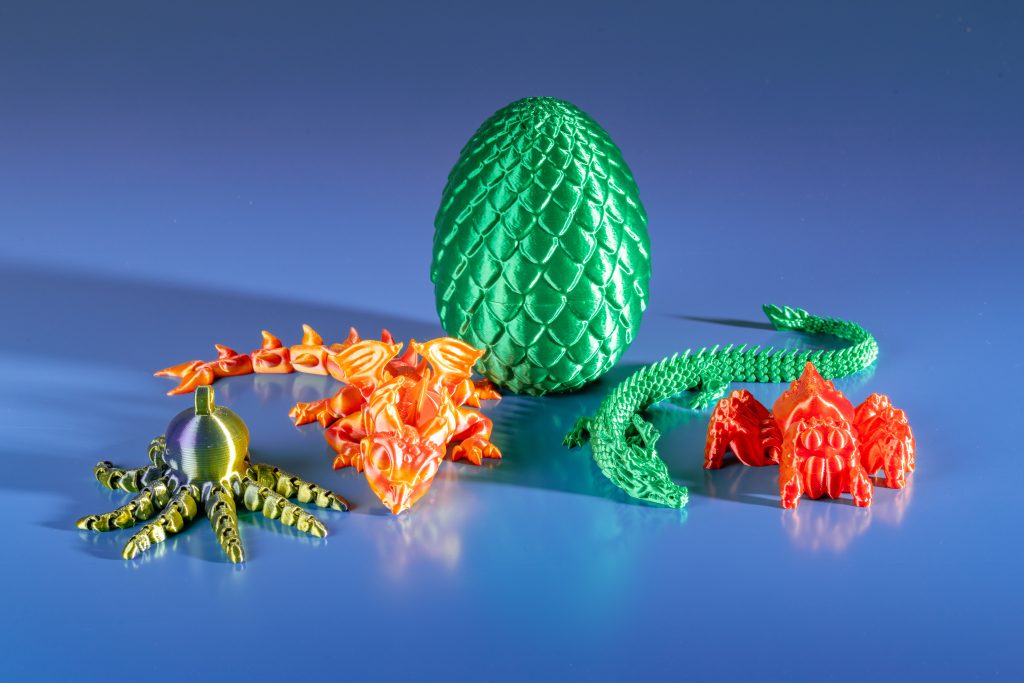

3D printing filaments made with Luminy® PLA have a stable diameter, which allows for excellent detail in the final print, exceptional visual qualities, layer adhesion, good stiffness, and dimensional accuracy and stability. Thanks to the biobased nature of Luminy® PLA it does not let off unpleasant smells or toxic fumes as it prints, making it a favorable alternative to ABS.

The most common Luminy® PLA grades used for 3D printing are:

In addition to home use, Luminy® PLA can be used in prototyping within the automotive, aerospace, consumer electronics, architecture, and manufacturing industries. Long-lasting items like home decor, furniture, and jewelry are made with Luminy® PLA.

"Combining Kexcelled's deep understanding of 3D printing consumables with TotalEnergies Corbion's expertise in PLA, we are forging a powerful alliance that benefits the entire 3D printing industry. This collaboration will yield significant advancements in consumer-grade materials, offering enhanced performance and exciting aesthetic options like heat-resistant and matte PLA, ultimately expanding the applications and appeal of 3D printing for a wider audience."

Wilson Mao - CEO & Founder of Kexcelled

Combining Kexcelled’s deep expertise in 3D printing consumables with TotalEnergies Corbion’s advanced Luminy® PLA, this partnership is expanding the potential of 3D printing across consumer and industrial sectors. By formulating high-performance materials such as heat-resistant and matte PLA, Kexcelled is unlocking new applications and aesthetic possibilities that broaden the appeal of 3D printing for a wider audience.

Our Luminy® PLA has an 85% lower carbon footprint compared to conventional plastics. It’s recyclable, compostable, and made from responsibly sourced sugarcane.

Our scientists and experts are always on call. We work alongside your team to help build new applications and ensure a smooth transition to sustainable solutions.

We are driven by our vision of a better world for generations to come.